Being prominent ceramic Fiber producer in India, we manufacture ceramic fiber modules using premium quality ceramic fiber blanket.

Divine ceramic fiber module adopts high-quality spun fiber blanket and it is folded and pre-compressed to specific densities. There are various anchor systems. The ceramic fiber module is a unique type of refractory furnace lining products aiming at simplifying and speeding up furnace construction and improving the integrity of furnace lining.

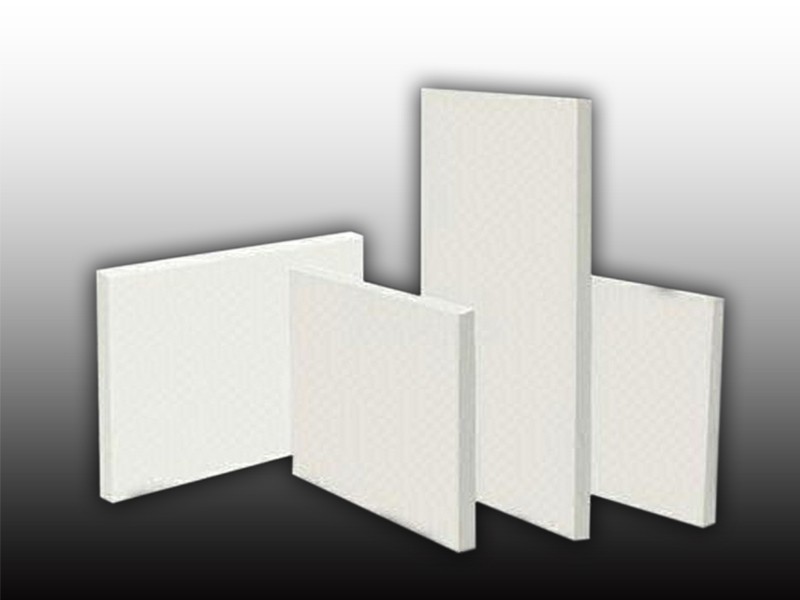

This product has clean and white color as well as formal dimension, which can be directly fixed on the anchor nail on steel plate for shell of industrial furnace with excellent refractory and insulating effect. Thus, it has improved the refractory and insulating integrity of furnace and pushed forward the progress of furnace construction technology. It features Fast and easy installation, Lower heat storage and fuel costs and so on..